Collision repair for aluminum and steel panels requires distinct approaches due to their contrasting properties. Aluminum, lightweight and corrosion-resistant, suffers minor dents and scratches, while steel's higher strength demands more intensive repair for deformities and buckling. Specialized services start with damage assessment, use advanced tools for removal, and employ color-matching technology for accurate paint restoration on aluminum. Steel panels may undergo sandblasting and require welding or bonding techniques. Rigorous quality control ensures structural integrity and aesthetic appeal. Choosing these collision repair services offers faster turnaround times, expert knowledge, high-quality materials, and adherence to industry standards, prioritizing vehicle safety and appearance.

In today’s automotive landscape, collision repair services have evolved to cater to a variety of materials, with aluminum and steel panels being prominent. This article delves into the intricacies of collision repair for these materials, exploring the unique challenges and benefits. Understanding the differences between aluminum and steel damage is key to effective repair. We’ll outline the process for each, highlighting specialized techniques and considerations that make these services indispensable in ensuring vehicles return to their pre-accident condition.

- Understanding Aluminum and Steel Panel Damage

- The Process of Collision Repair for These Materials

- Benefits and Considerations for Choosing Specialized Services

Understanding Aluminum and Steel Panel Damage

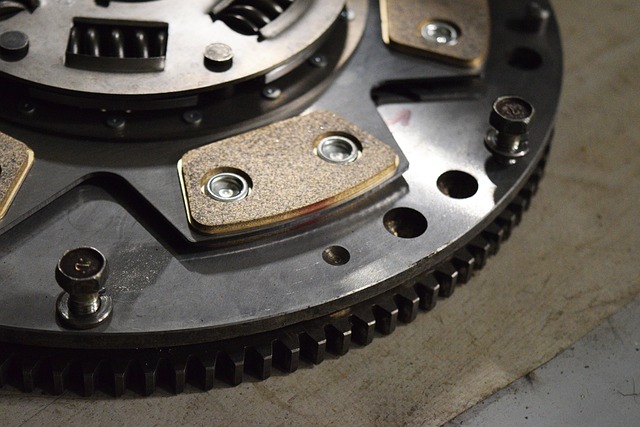

Aluminum and steel panel damage can arise from various incidents, including accidents, weather events, or even accidental damage during routine maintenance. Recognizing the unique characteristics of each material is crucial for effective collision repair services. Aluminum, known for its lightweight nature and corrosion resistance, often experiences dents, scratches, and dings without significant structural compromise.

In contrast, steel panels are more prone to deformity, buckling, and penetration due to their higher strength-to-weight ratio. Collision repair techniques for these materials vary accordingly; dent removal or paintless dent repair methods can be highly effective for aluminum, while steel may demand more intensive automotive collision repair procedures to restore its structural integrity and aesthetic appeal.

The Process of Collision Repair for These Materials

The process of collision repair for aluminum and steel panels involves several meticulous steps to ensure structural integrity and aesthetic restoration. It begins with a thorough inspection to assess damage, including dents, creases, and cracks. Skilled technicians use specialized tools to remove damaged areas, often employing water jet cutting or hand tools for precision. Once the panel is prepared, they proceed with either steel welding or aluminum bonding techniques to repair the frame.

For aluminum panels, vehicle paint repair becomes a critical component. Technicians must match the original paint as closely as possible using advanced color-matching technology. This involves applying primer and then layers of paint, allowing each coat to dry thoroughly. Steel panels, on the other hand, may require sandblasting for a smooth finish before painting. The final step involves quality control checks to ensure the repair matches the vehicle’s original specifications, providing both structural strength and visual appeal in what is often considered a delicate process within automotive repair services.

Benefits and Considerations for Choosing Specialized Services

Choosing specialized collision repair services for aluminum and steel panels offers numerous benefits. These professionals are equipped with advanced tools and techniques tailored to handle the unique challenges posed by these materials, ensuring precise and effective repairs. Specialized services can offer faster turnaround times compared to general body shops, as they have the expertise and resources dedicated to complex car damage repair processes, from metal fabrication to intricate paintwork restoration.

When selecting a collision repair service, consider their experience with specific types of car paint services for aluminum and steel, as well as their commitment to quality and customer satisfaction. Reputable body shop services prioritize using high-quality materials and adhering to strict industry standards to guarantee long-lasting results. This specialized approach not only ensures the safety and structural integrity of your vehicle but also revitalizes its appearance, making it a wise investment for car owners seeking top-notch repairs.

Collision repair services, especially tailored for aluminum and steel panels, offer advanced solutions for vehicle restoration. By understanding the unique characteristics of these materials and employing specialized techniques, professionals ensure precise repairs and enhanced vehicle performance. Choosing a reputable collision repair shop with expertise in these materials provides peace of mind, guaranteeing not just visually appealing results but also structural integrity, which is paramount for safety.