The collision repair services industry has evolved from manual to advanced technological practices, including CAD, laser measurement, and robotic welding, revolutionizing repairs with precise measurements, faster turnarounds, and enhanced quality. This multi-step process starts with inspections using diagnostic tools, followed by frame straightening with specialized equipment, addressing both structural and cosmetic defects. Advanced technologies ensure efficient, high-quality repairs, but competition demands constant skill updates to meet evolving vehicle standards.

In today’s digital era, understanding structural realignment within collision repair services is more crucial than ever. The evolution of collision repair techniques has revolutionized the industry, shifting from traditional methods to advanced, precision-based practices. This article explores key components of the structural realignment process, highlights benefits and challenges in modern collision services, and provides insights for folks navigating this complex landscape. By delving into these aspects, we aim to enhance your understanding of collision repair services as a game changer in automotive restoration.

- The Evolution of Collision Repair Techniques

- Key Components of Structural Realignment Process

- Benefits and Challenges in Modern Collision Services

The Evolution of Collision Repair Techniques

The world of collision repair services has undergone a remarkable transformation over the years, evolving from traditional, often manual methods to highly advanced technological approaches. In the past, collision repair was primarily focused on fixing structural damage to vehicles after an accident, with a heavy emphasis on metalworking and welding. Skilled technicians meticulously realigned panels, straightened frames, and restored damaged cars to their pre-collision condition. However, this process was time-consuming and required significant manual labor.

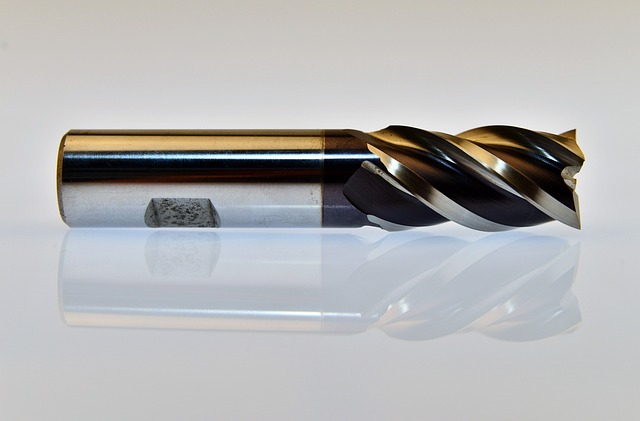

With advancements in technology, the industry has embraced innovative techniques and tools that streamline the collision repair process. Modern collision repair services now incorporate computer-aided design (CAD) systems, laser measurement technologies, and robotic welding machines. These advancements enable precise measurements, accurate panel alignment, and efficient repairs. The integration of digital solutions not only enhances the accuracy of vehicle restoration but also reduces the overall time and cost of auto maintenance. As a result, customers benefit from faster turnaround times and superior bumper repair quality, ensuring their vehicles return to their original condition after any collision-related incidents.

Key Components of Structural Realignment Process

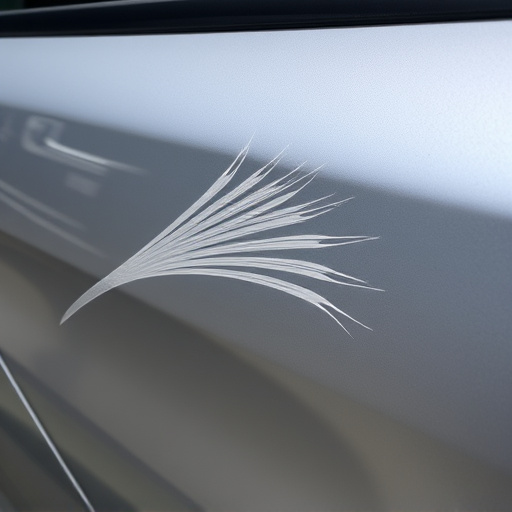

The structural realignment process in collision repair services involves several key components that ensure the safety and aesthetic integrity of vehicles. It begins with a thorough inspection to identify damage, including frame bends, misalignments, and deformations. Advanced diagnostic tools are employed to pinpoint these issues accurately. Once detected, specialized equipment like hydraulic presses and frame machines are used for frame straightening, meticulously realigning the vehicle’s structure to its original factory specifications.

This meticulous process extends to vehicle body repair, where skilled technicians address dents, scratches, and other cosmetic defects. For classic car restoration enthusiasts, structural realignment is paramount to preserving historical vehicles’ original integrity while ensuring they meet modern safety standards. The integration of advanced repair techniques and traditional craftsmanship guarantees that restored classics not only look their best but also drive as well as new.

Benefits and Challenges in Modern Collision Services

In today’s digital era, collision repair services have undergone a significant transformation, offering both enhanced benefits and novel challenges. One of the key advantages is the integration of advanced technologies such as computer-aided design (CAD) and robotic welding, which ensure precise and efficient repairs. These innovations not only speed up the process but also improve the overall quality of car collision repair, making vehicles nearly indistinguishable from their pre-accident state.

However, navigating modern collision repair services comes with its own set of complexities. The increasing demand for these services has led to a bustling landscape of collision repair centers, each vying for customers. This competition, while fostering innovation and improved service quality, can also create challenges in terms of ensuring consistent standards across different facilities. Moreover, keeping up with the constant evolution of vehicle models and complex paint jobs is a daunting task, requiring specialized skills and knowledge in car paint repair to maintain flawless results.

Structural realignment in collision repair services has evolved into a sophisticated process, combining advanced techniques with precise technology. By understanding the key components involved and acknowledging both the benefits and challenges, collision centers can enhance customer satisfaction and stay competitive in today’s market. Embracing these advancements ensures efficient repairs, reduced downtime, and improved vehicle aesthetics, ultimately positioning collision repair services as indispensable in the automotive industry.